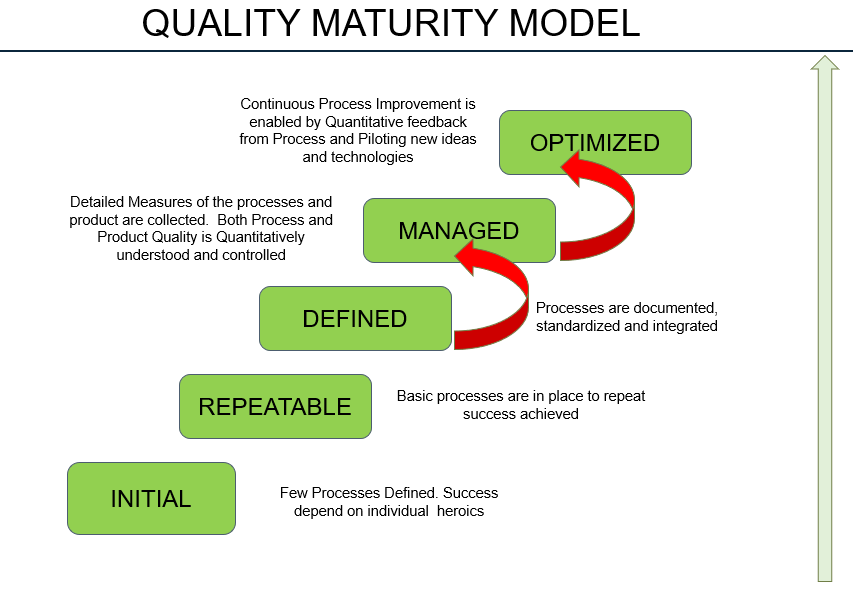

As a consulting organisation we take pride in our razor-sharp and timely analysis, helping the stakeholders make faster decisions and thus achieve the desired results. While an early engagement is desired for best quality results, we engage at multiple stages for the different organisations. A stage is an indicator of the current level of the organisation in terms of maturity.

A more desired engagement model is when we can engage with the customers and teams at an earlier stage and can help them in identifying their readiness and missing pieces in their Maturity Model.

In some cases, our engagement is directly into an investigation project for a product that has already seen some actions taken from the customers, but still desired results are not yet achieved. This is a trial-by-fire stage and generally the most demanding one as the pressure to get a result is the biggest at this stage. We term the pressure as the biggest since the timelines presented are short. We often are expected to do our magic in the shortest of the timelines presented.

With years of experience in working on pharma and manufacturing we have identified the key components that result in degradation or the status quo.

What doesn’t help

It’s best to talk about what doesn’t help an organisation before we can move to what it takes to run a successful project.

- Lack of mandate to improve

- Lack of accountability

- Lack of Willingness to:

- Accept and change.

- Invest in tools and skills.

- Document and share knowledge.

- Silos in the organisations

- Lack of Analytical skills

- Lack of data strategy

- Digital infrastructure

- Unavailability of data

What Helps

To run a Business Excellence project in Manufacturing successfully we need:

- Mandate and Time from the SMEs from Manufacturing to participate in the reviews.

- SME willingness to share the knowledge and challenges that only a seasoned practitioner knows.

- SMEs’ and Data Analysts’ willingness to share Historical data for the problem at hand.

- Data Science experts with required Analytical skills

- Willingness and Openness to Participate in the reviews, raise questions, challenge interpretations and provide answers

- Mandate for the Operations Excellence and Manufacturing team to run the controlled tests per the recommendations and bring back the results.

We follow the industry proven Six-Sigma DMAIC methodology, and we know that to get to the desired results consistently, it is best to avoid any shortcuts. We shall cover this as a separate article.